Cigeo funicular: the first tests carried out soon

Tests will be carried out on a prototype will verify that the future funicular will safely transport the packages of radioactive waste from the surface to the underground disposal facility. The first tests will start next October, in a facility that just has been completed.

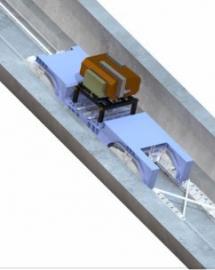

After several months of upgrading and adapting an unoccupied hall on the Froncles industrial site, the new building is ready to accommodate the prototype of the future Cigeo funicular. This innovative and non-standard transport device will allow the safe transfer and routing,

on a 4 km long slope, inclined at 12%,of the transfer casks containing the packages of radioactive waste from the surface to their final storage position, 500 m underground, in the underground galleries of Cigeo.

But pending the completion of Cigeo and the funicular, the construction of a "test bench" is a crucial step. "The funicular prototype and its test bench, explains Jean-François Hervé, head of the mechanical equipment and processes department at Andra, will make it possible to test the technology used at real size. The challenge: to build all the necessary environment (tracks, steel structure, etc.) to be representative of teh actual conditions, and to perform performance tests on the various braking systems.

A test bench for life-size tests

This machine built by the company Poma, which specializes in the manufacture of cable transport systems, is the first of its kind. "Usually, on already existing technological installations or processes, the practice wants that one resorts to the feedback of experience to adjust the equipments, continues Jean-François Hervé. First of all, we will have to demonstrate that this test bench fully recreates actual conditions, and that if we do tests, these will be 100% reliable. The test bench will thus be used to qualify the elements which are important for safety, such as the braking systems on board the funicular. "

The first tests will therefore focus on the emergency stop brakes, the emergency brakes or the end-of-lane shock absorbers.

“The on-board system implemented on the funicular makes it possible to“ split ”safety braking equipment and uses particularly innovative technologies. We will verify that it works as we have defined. "

See you in 2021 for the first results of the braking tests.

A FUNICULAR UNIQUE IN THE WORLD, BUILT LOCALLY

A French company based in Isère, Poma is one of two companies in the world to build funiculars, usually intended for ski resorts, but increasingly used in urban transport and industry. For the design of the Cigeo funicular, Poma has worked for many years in close collaboration with the project teams and in partnership with companies in the nuclear engineering field. The establishment of the test bench in Haute-Marne makes it possible to further develop these partnerships and to anchor technological development in the local industrial framework. This work is already well underway since 80% of the purchases for setting up and building the test bench have been allocated to local companies (metal structures, electrical and mechanical engineering, etc.).