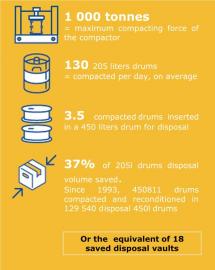

How to save disposal volume capacity? The key role of the compactor at the CSA

Saving the volume available for the disposal of radioactive waste is a central issue. While techniques exist upstream of disposal to limit the production of waste, at the Aube disposal facility (CSA), the compacting press plays a key role, by reducing the volume of some of the waste packages received. Here's how it works..

What is the compacting press used for?

Available disposal volume is a scarce resource.

Reducing the volume of certain low- and medium-level, mainly short-lived (FMA-VC) waste packages is one of the solutions for optimizing this available space.

This is the job of the compactor.

What types of waste are compacted?

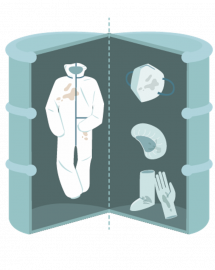

Mainly protective clothing, vinyls, gloves ... from nuclear facilities or from hospitals (research laboratory, radiotherapy departments).

This is low density waste.

How does it work?

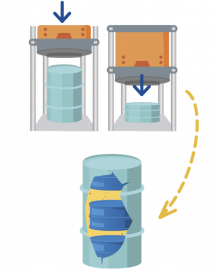

Waste that can be compacted is received at the CSA only in 205 liter metal drums. Introduced into the press, these waste packages are compacted and take the form of “pucks”.

These are then packaged in new, larger packaging (450 liter drums). Last operation: the drums are filled with concrete to fill the voids between the pucks and immobilize them. After concrete has cured, these new packages are now ready to be disposed of!

From reception to disposal at the CSA...