Virtual reality, artificial intelligence, drones ... innovation in the service of radioactive waste management

For more than three years, Andra employees have been mobilized within the framework of an innovation process, promoting collective intelligence, openness and co-construction. Focus on 4 innovative projects.

One of the objectives of Andra’s innovation approach is to imagine projects to optimize the management of radioactive waste, by anticipating regulatory, societal, scientific or technological developments. It is in this context that many small and large projects have emerged. Focus on four of them: the use of drones to monitor the condition of the disposal facilities at the Aube Disposal Facility (CSA); the Jaugeauto project to reactively monitor flow variations in rivers as part of environmental monitoring; E-SI, a device that could ultimately improve the monitoring of facilities facing the risk of fire; Finally, "2.0 training" for producers of radioactive waste to enable them to benefit effectively from Andra's expertise in waste management and disposal.

Drones in the sky of the CSA

At the Aube repository (CSA), radioactive waste is disposed of in large reinforced concrete vaults, 25 meters on each side and 8 meters in height. These structures are sealed and waterproofed with a membrane made of polyurethane resin, which prevents water infiltration.

To ensure that the membrane remains effective, its condition and behavior over time are checked regularly. Until now, technicians have climbed the buildings to spot any defects in the coating (peeling, tearing, crack, etc.). This is a risk for the personnel who had to work at height.

A CSA team then thought of using drones to monitor the condition of the membranes. They take pictures of the disposal vaults, in all dimensions, and provide high-resolution photos of the works. The photos are then integrated into 2D or 3D modeling software, which allows Andra's experts to decide whether a membrane intervention is necessary. In addition to improving safety for the personnel working on the site, this innovation enables checks to be carried out more regularly and with greater precision.

Jaugeauto, a smart solution for measuring the flow of rivers

Monitoring of watercourses as part of environmental monitoring activities is essential, especially for Andra's facilities. Until now, flow measurement could only be done by involving technicians directly in the field. This process was sometimes difficult to carry out, because of the risks associated with meteorological conditions (in the event of floods in particular), or because variations in the flow can occur suddenly.

As part of an internal call for ideas, a team from Andra has developed the Jaugeauto project, a new device which enables these measurements to be carried out automatically. The innovation of this system lies in the use of communicating sensors: thanks to a fluorescent food tracer injected into the waterways, the flows can be measured remotely, without human intervention being necessary. The intelligent device can trigger a calibration on its own based on the data already acquired and regulate the quantity of tracer in complete autonomy.

In particular, this will limit the risk of accidents in the event of an intervention. While Jaugeauto is currently intended for use within Andra, it could eventually be used in other areas of activity.

E-SI: artificial intelligence to assess the heat load at a glance

On its facilities, regulations require Andra to keep an up-to-date inventory of the heat load of the premises, that is to say of the quantity of heat potentially released in the event of a fire This depends on the nature and the number of objects present on a site. The inventory makes it possible to identify the potentially most dangerous places in the event of a fire breaking out.

Today, the operation is carried out manually: an employee inspects each building and notes the equipment present. A process that takes time and represents a significant cost.

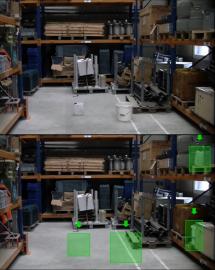

Thanks to Andra’s innovation project, a new device has been devised: E-SI. This tool, still in development, would eventually make it possible to scan all the objects present in a room and assess their heat load. E-SI could identify objects and their composition directly from a picture. The heat load would then be deduced from this data.

Since December, a prototype allows, from two photos, to identify objects added or removed. Its reliability will be be improved, but eventually E-SI will be able to identify objects with precision. This technology, which uses artificial intelligence, is also likely to be transposed to other uses, such as the remote monitoring of premises .

Virtual and immersive training

Since 2012, Andra has offered a range of professional training courses for producers of radioactive waste. These aim to explain and detail the different processes for accepting and managing radioactive waste at Andra. Specific requirements are imposed on producers such as EDF, Orano, or the CEA so that waste packages can be safely disposed of by Andra. These trainings allow them to directly benefit from the expertise of the Agency.

Recently, the dedicated "training 2.0" working group proposed several improvements to the existing training. After having collected the needs of producers and using the expertise from companies specializing in digital technology and education, Andra now wishes to transform some training courses by making them more immersive. The specifications have just been completed and the objective is to use a modernized format, that could be used whether at Andra facility in the Aube or directly at the waste producers thanks to virtual reality, models , and 360 ° photos. Visualizations in 3D covering the complete life of the disposal structures could be offered that way.

Beyond improving the user experience, immersive training makes learning better, faster, and more interactive.