A specific solution for VLLW

Radioactive waste management has evolved over time. Over 40 years ago, France decided to dispose of radioactive waste in industrial repositories, as it represented a safe and sustainable management solution . The disposal facility for VLLW was put into operation in 2003 in Aube.

VLLW is disposed of in a dedicated facility, the first of its kind in the world.

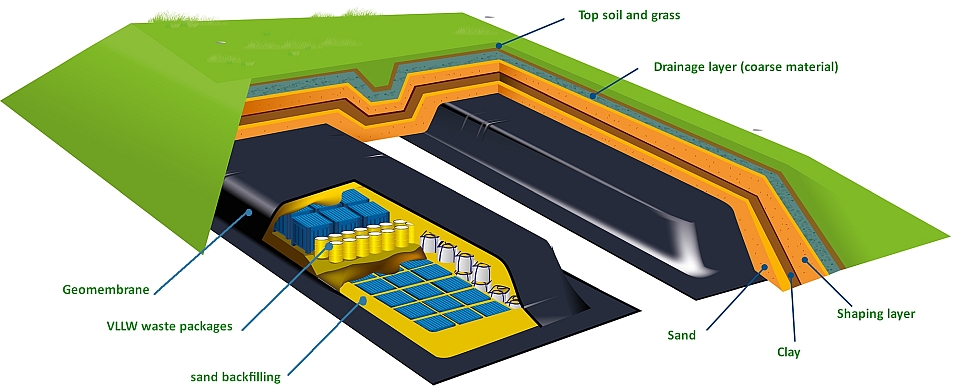

Here, about 30,000 m3 of radioactive waste is disposed of yearly, in trenches 176 m long and 25 m wide dug several metres deep in a clay layer. Once filled, these trenches, or cells, are covered by a capping system composed of natural materials and a geomembrane, ensuring watertightness.

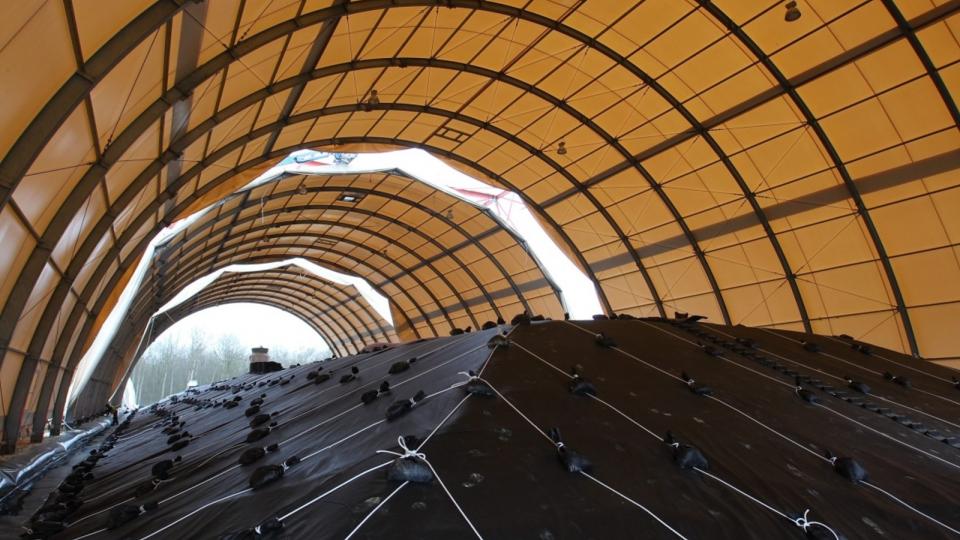

All operations from the construction/digging of the trench to the preliminary capping are conducted while protected from the outside, under the a mobile shelter. These mobile shelters, developed and patented by Andra, and known as Prémorail, can be moved from one trench to the next one by means of rail-sliding system.

In order to guarantee the long-term protection of humans and the environment, the containment of waste is ensured, in each disposal trench, by two distinct and complementary barriers:

- a high density polyethylene geomembrane lining covering the bottom and the edges of the cell before disposal. The same kind of upper lining, covering the waste pile, is sealed to the bottom liner, after the trench is filled

- an envelope of natural clay materials guaranteeing a very low permeability. The upper part of this envelope, called a definitive capping layer, is made of a several layers of different materials separated by the geomembrane. Each layer plays a specific role in the sealing of the trench or the drainage of rainwater. All the materials used for the final cover, except the draining material (aggregates), are already present on the site. They are recycled from the natural materials dug out during disposal trench excavation.

Operations

Disposal cells are excavated progressively, as needed, directly in the clay layer down to a depth of 8 m and are operated one-by-one. Cell design has evolved to maximize the disposal volume, and now offers 34 000 m3 of volume in a 26 m-wide by 174 m-long and up to 8.5 m deep structure.

The trenches are filled up with waste packages in successive layers (about 10 on average), while the voids between waste packages are gradually backfilled with sand.

- a 2-mm-thick high-density polyethylene (HDPE) geomembrane liner is first fitted at the bottom and on the sides of the cell before the start of the disposal. Once each individual cell is filled, the same kind of liner is placed over it and thermo-welded to the bottom liner, in order to form a continuous and water-tight barrier around the waste. The geomembrane is fully waterproof and is designed to prevent any dispersion of radioactivity and any seepage of external waters (rain, infiltrations) for several decades

- a containment envelope made up of natural clay-based materials. The lower part of the envelope corresponds to the first 5 m of the clay layer located immediately under the geomembrane liner and characterized by a very low permeability (at least 10-9 m/s). The upper part is made of clay-based materials that were removed during cell excavation and consists of a layer measuring 1 to 5 m in thickness, shaped and compacted mechanically in order to restore its initial low permeability (at least 10-9 m/s).

- Then, a clay backfill, approximately 2.5 m in thickness, will isolate the clay-based containment layer from: - weathering (frost, draught); - burrowing animals, and - erosion.

- Ultimately, a permanent 30 cm thick layer of grass-covered topsoil is laid over the capped cell or cells.

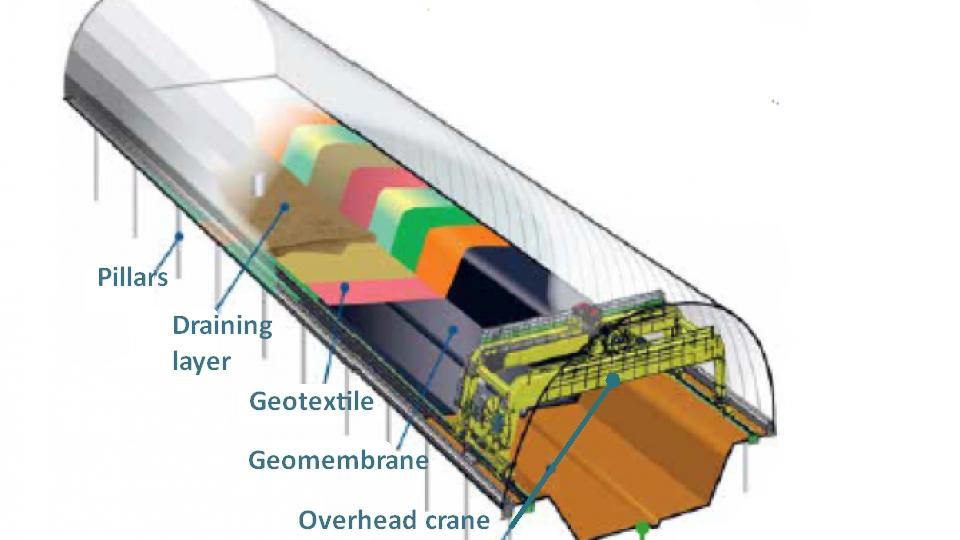

Disposal Trench for Large-Size Waste

A specific trench dedicated to large-size waste was opened in 2017.

This new disposal cell is 265 m long and 22 m wide, and offers a disposal capacity of about 35,000 m3. This cell is dedicated to large waste items, especially from the decommissioning of nuclear installations. A hundred 9 meter-deep piles located around the cell allow operation of an overhead crane with a lifting capacity of 130 tons.

This new cell anticipates the future needs of the dismantling program, while offering improved safety and comfort to the operators, and optimizes the management of VLLW.

Compaction of VLLW

The CIRES has two compactors to reduce the volume of compactable waste:

- a compactor with a capacity of 300 tons, suitable for compacting light scrap metal

- a baler, with a capacity of 120 tons, dedicated to low density waste (plastics, heat insulation ...).

In 2016, 938 m3 of light scrap was compacted by the compactor. A reduction rate of 6.2 was achieved. At the same time, 2,151 m3 of plastic waste compacted by the baler, with a reduction rate of 2.9.

Radiological monitoring

In 2016, more than 1,500 radiological analyzes were performed. The main atmospheric parametres measured are presented below:

Atmospheric monitoring

- Atmospheric station: measure of the radioactivity in the air (gas and dust)

- Conditioning Workshop stack: measure of gaseous effluents

- Storm and regulation basins: radiological, physical and chemical analysis of water. Measure of liquid effluents

- Samples for radiological analyzes and physico-chemical waters. Stream Monitoring

- Hydrobiological monitoring. Sampling for aquatic plants analyzes. Aquatic Ecosystem Monitoring Ecosystem

- Area of moss sampling for radiological analysis

- Analyses of the food chain (milk, leafy greens)

- Monitoring of ambient radiation level

- Radon monitoring

- Piezometers: measuring the watertable depth and radiological and physico-chemical analyzes